Solutions designed to solve your problems.

We have the capability to help you with everything from custom automation to complex progressive dies. We’d love to talk to you about your next project.

Custom Automation

While some machine builders will start with the same frame and modify tooling to make their job easier, we build adjustable smart modules so that we can create equipment to fit your plant layout and processing needs. Your product requires specific processing parameters, while your manufacturing facility dictates flow or form, so we build to meet your needs.

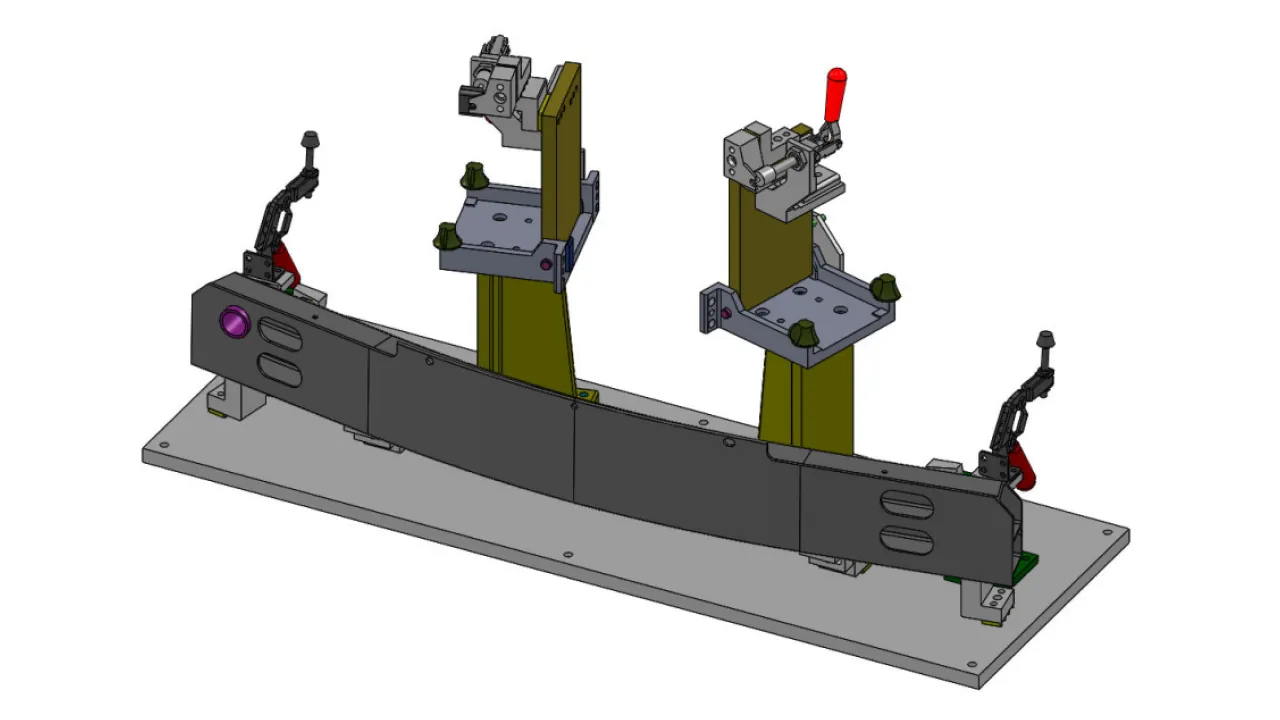

Prototype Fixtures

Prototypes can be a large program expense, so Pyper offers our customers simple, repeatable prototype fixtures to enable them to build their own prototypes during the development process of their tools. These tools can also help validate designs and processes.

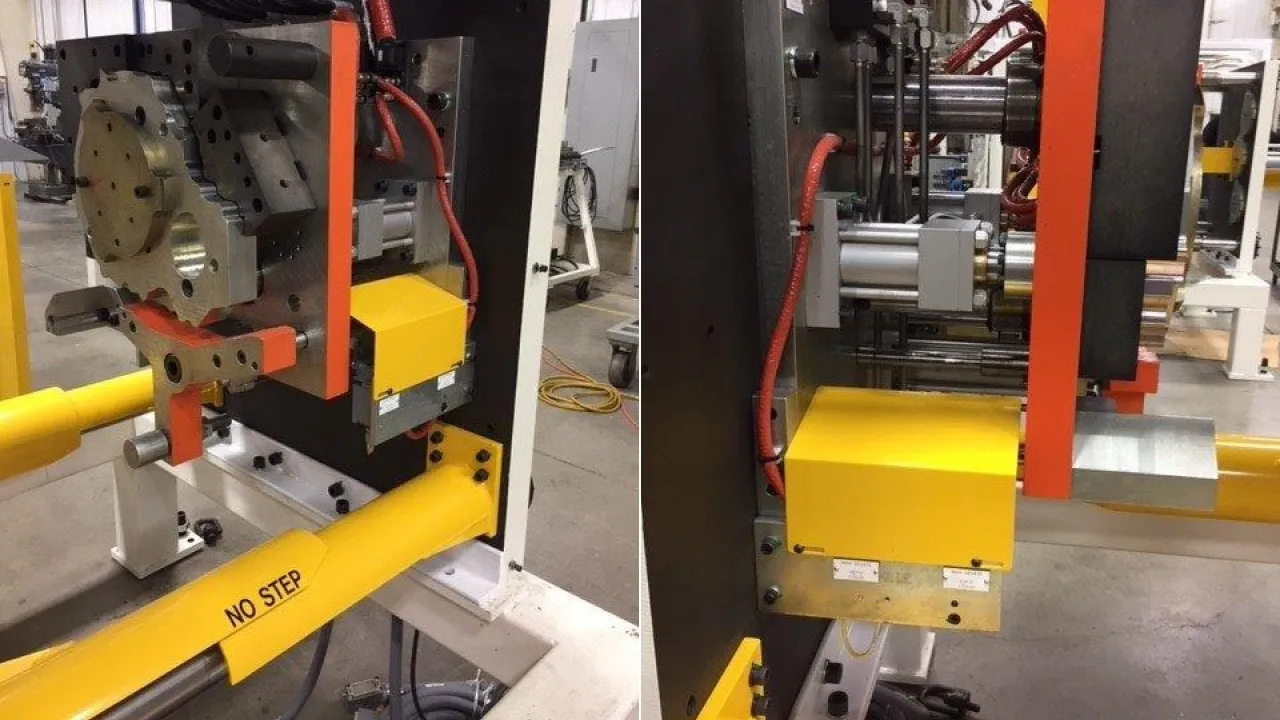

Stand Alone Machines

Individual, stand alone machines are designed for specialized, individual tasks within your manufacturing process. These robust, reliable machines provide optimal performance and are easy to integrate into your production facility.

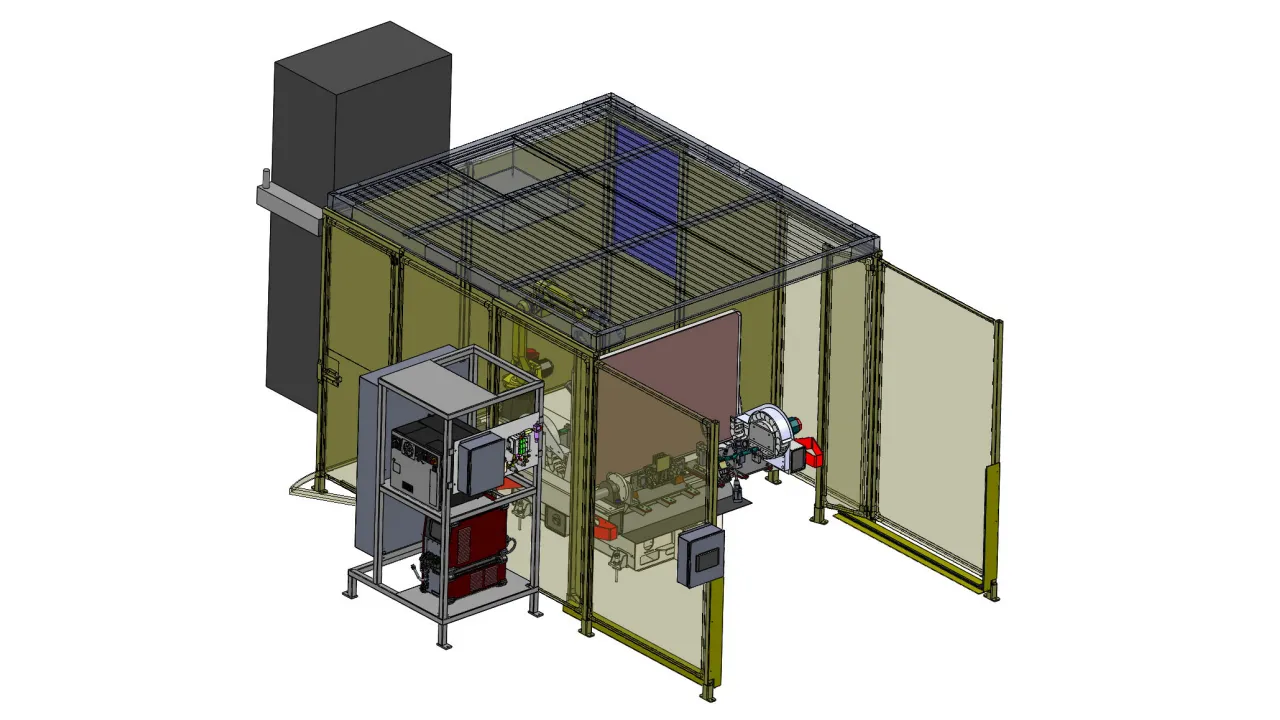

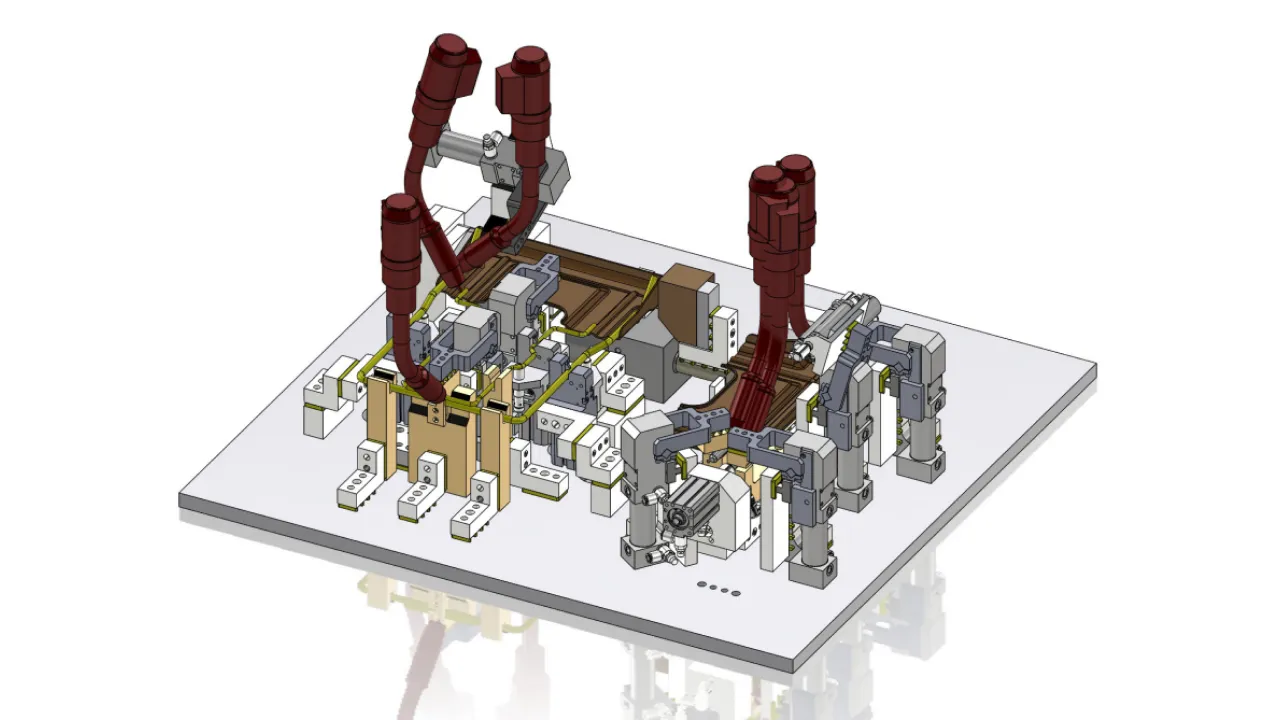

Integrated Cells

Our Integrated Cells offer a full process stream. They act as a single, cohesive unit, streamlining your production process and providing reliable part tracking. This approach enhances efficiency, minimizes downtime, and maximizes output, ensuring your manufacturing goals are met with ease.

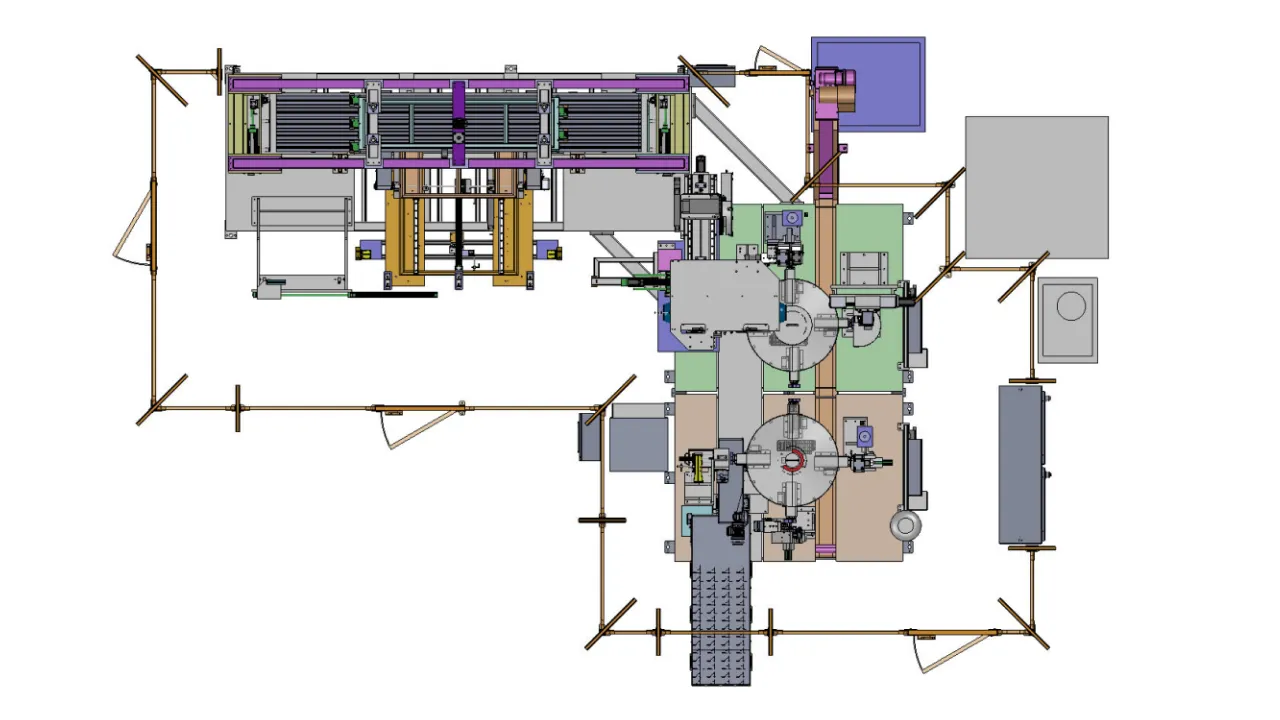

In Line Transfer Systems

Depending on your floor layout, in line transfers can provide an accurate handoff system. Our In Line Transfers solutions enable seamless movement of workpieces between various stations in your production line. With our reliable and efficient systems, you can reduce manual handling and improve overall placement and productivity.

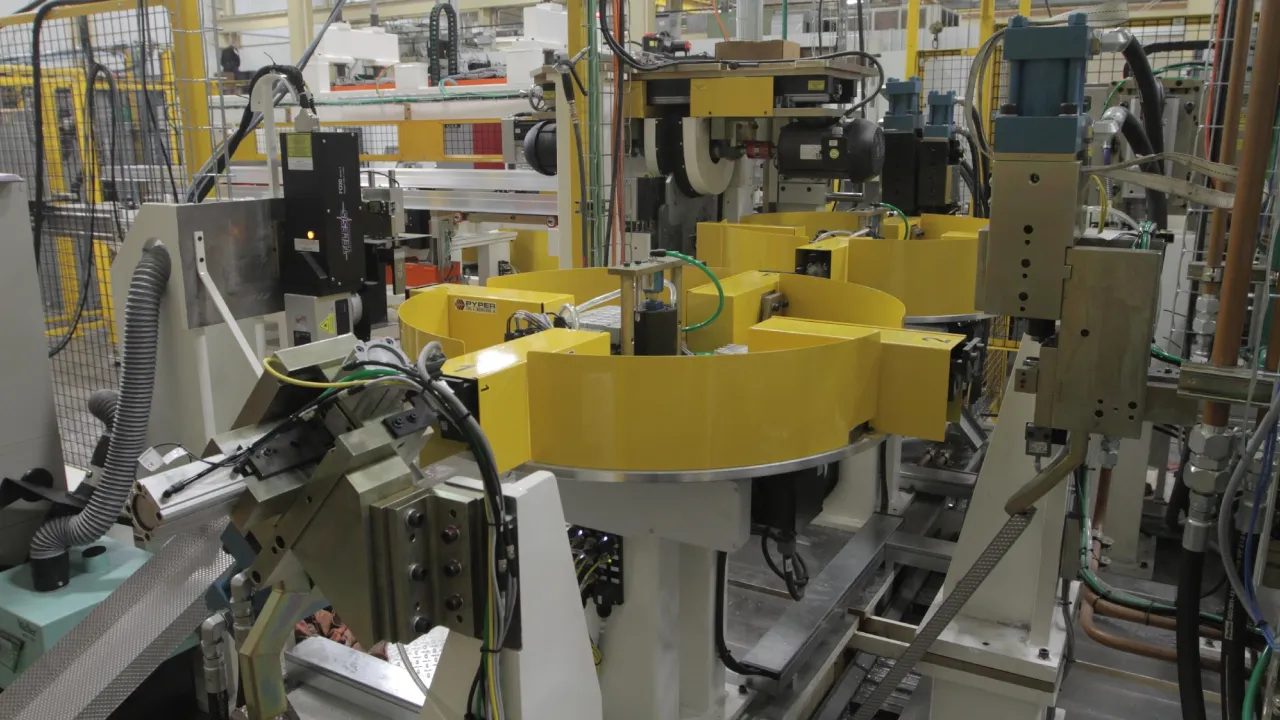

Single Turntable Systems

Our Single Turntable system provides a compact, efficient solution for handling and processing parts. These versatile machines enable quick and precise indexing between operations, maximizing productivity and minimizing floor space requirements. Often parts remain in a single nest and are processed to completion, but these single turntables can also work well with offline equipment integrated with them.

Multiple Turntable Systems

When a process is more complicated than a single turntable system, but the same attributes of a single system are needed, multiple turntables can be employed. Transferring parts between turntables is not difficult and allows for seamless transitions between different processes. This solution optimizes your workflow, reduces downtime, and increases overall efficiency.

Operator Load

When operators are available to load equipment, our machines empower your workforce to efficiently load and unload parts in your production line. These machines are ergonomic, user-friendly solutions to ensure safe and efficient handling of parts, maximizing both productivity and worker satisfaction.

Robotic Load

With the current market, finding enough capable operators is difficult, so we sometimes use advanced robotics to automate the loading and unloading tasks in your manufacturing process. This innovative solution reduces manual labor, improves consistency, and accelerates production.

Single Robot

Our Single Robot solutions integrate a versatile, high-precision process appropriate robot into your production line. With the correct tooling, robots weld, sand, while still others, handle tasks like palletizing. This technology enhances automation capabilities, streamlines processes, and improves overall efficiency.

Multiple Robots

Our Multiple Robots offering employs a team of coordinated robots, working together to maximize efficiency and productivity in your manufacturing operations. This advanced solution ensures consistent, high-quality results across all processes.

Metal Processing

We offer equipment to weld, machine, degate, bend, form and trim for a wide range of metals. We’re experts at integrating specialty equipment (e.g., robots, welders, saws, drills, sanders) to help produce a high-quality end product.

MIG Welding

Our MIG welding equipment delivers high-quality, durable welds for a variety of metals and applications. Using this versatile welding technique, our equipment ensures strong, consistent bonds for your parts.

TIG Welding

Our TIG welding equipment provides precise, high-quality welds for even the most intricate and complex metalwork. With our machines, you can trust that your parts will have clean, accurate welds with minimal distortion.

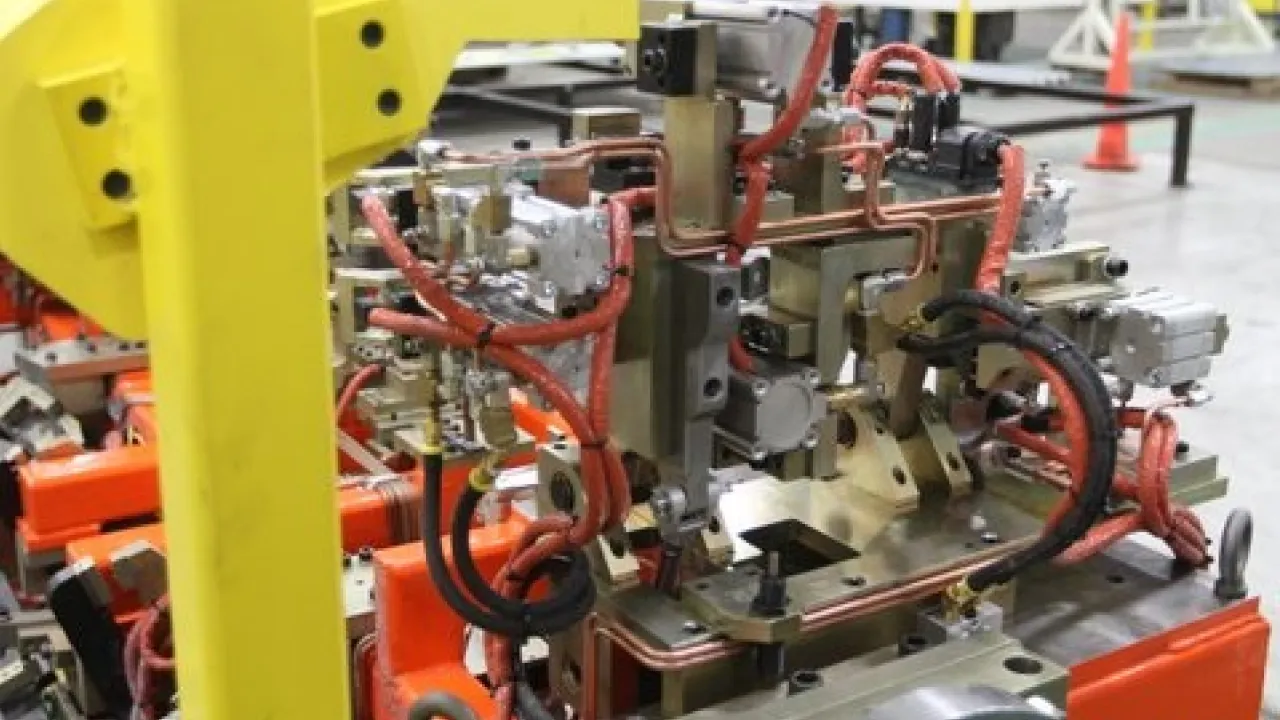

Resistance Welding

Resistance Welding offers efficient and consistent joining of metals with minimal heat input, and we’ve built a lot of equipment to do just this. This straight forward technique ensures strong bonds, reduced distortion, and quick turnaround times for your program.

Machining

Our Machining services provide accurate, high-quality parts using advanced tools and equipment. Trust our expert machinists to deliver precision components that meet your exact specifications. Our manufactured machining cells can also do everything from unstacking your pallet, to sawing the raw blank, then finishing the detail for shipment.

Trim Dies

Trim Dies is one area that we benefit greatly from the coordination between our automation and progressive die groups’ vast expertise. Our Trim Dies ensure clean, precise edges on your metal components and your tooling will be made to last. Our expertly crafted dies ensure consistent, high-quality results, streamlining your production process.

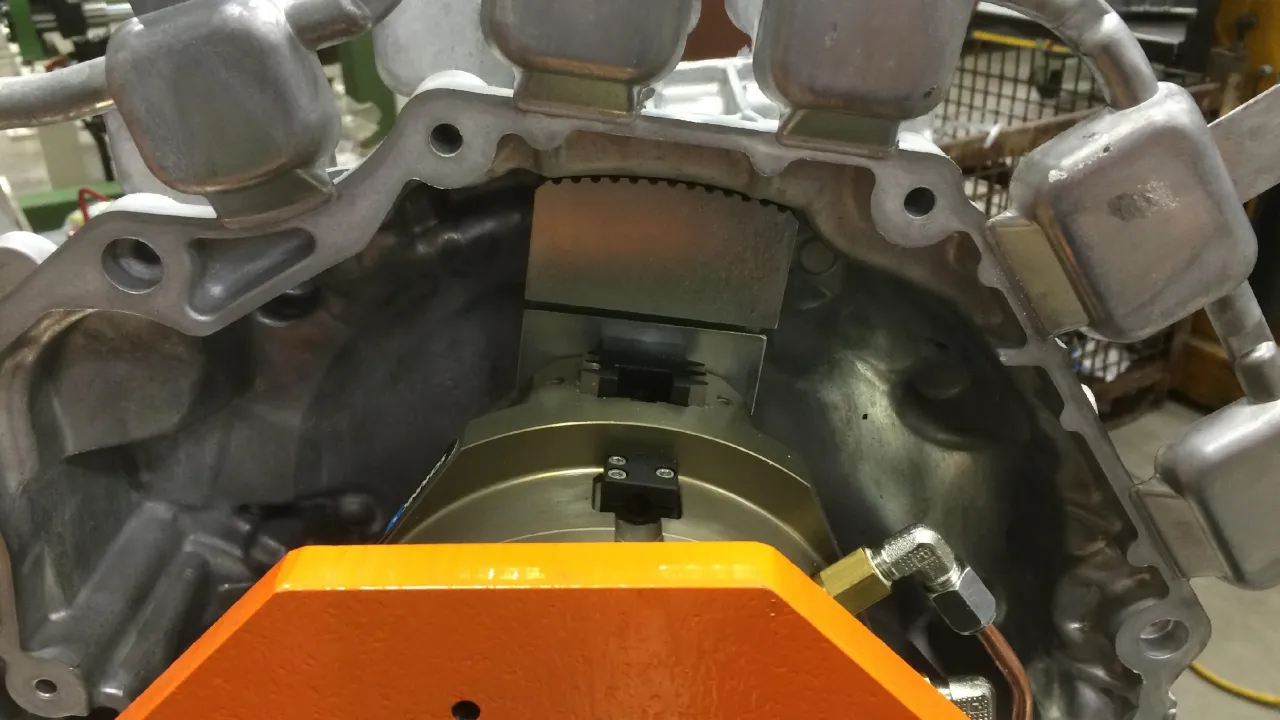

Degate

Our Degate equipment has historically included everything from the end of arm tool for the robot presenting the casting, to the actual degate machine. Interchangeable tooling is often a part of the package as well, to provide maximum use of a relatively simple tool. Our attention to detail on these machines is second to none.

Bending

Our Bending equipment provides precise control for the shaping of metal components to meet your design specifications. With our state-of-the-art equipment and skilled technicians, we ensure accurate, consistent results for your program.

Forming

Our Forming tools expertly shape metal components to fit your unique design requirements. Using advanced forming techniques, we deliver high-quality, custom parts that adhere to your specifications and maintain structural integrity.

Stamping Dies

Pyper simulates, designs, and builds progressive, line and transfer dies with experience processing parts from aluminum, high-strength steel, dual phase, and other material types to exacting tolerances. Pyper specializes in providing innovative die solutions up to 72” wide x 132” long in a single die, or longer with a split die set. Our efficient, high quality, and robust dies will increase your productivity, reduce your material waste, and ensure consistent high-quality results for the life of the tool.

Progressive Dies

Our Progressive Dies are designed and built to streamline your stamping process by performing multiple operations in a single tool.

Transfer Dies

Our team will strive to design you a robust Transfer Die that optimizes SPM and ensures consistent high-quality results for the life of the tool. Our team works to design a transfer die that integrates seamlessly with a transfer system and is built to make sure that startups are as flawless as possible.

Line Dies

Our Line Dies are designed and built to create easy hand transferring between stations, without sacrificing accuracy, quality or robustness.

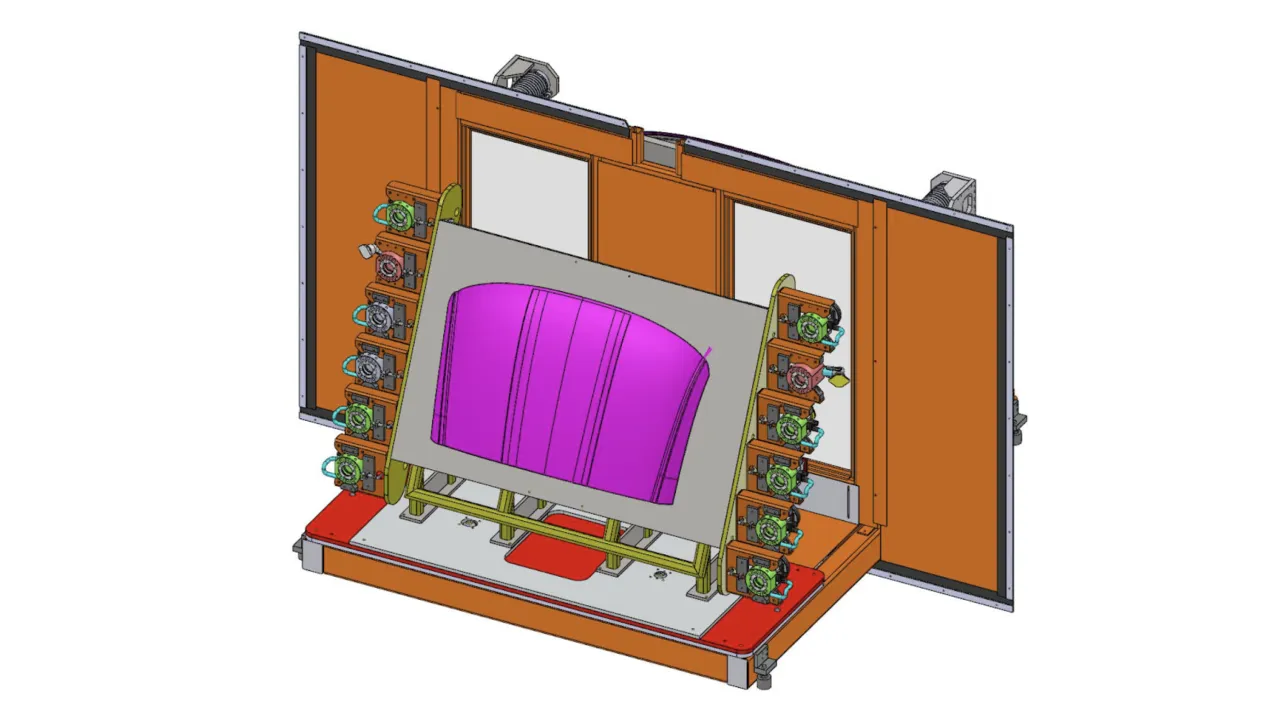

Carbon Fiber Processing

Pyper’s expertise extends into carbon fiber applications. We combine art and science to produce high-quality, flexible equipment for assembling and finishing carbon fiber products — allowing us to eliminate scrap and save costs.

Interchangeable End of Arm Tooling

Our Interchangeable End of Arm Tooling solutions enhance the versatility of your robotic systems. With easily swappable tools, your robots can quickly adapt to different tasks, increasing efficiency and productivity in your production line.

Assembly

Our Assembly solutions bring together components to create finished products with precision and efficiency. Trust our skilled technicians to ensure proper fit and function while maintaining high-quality standards and quick turnaround times.